We are now much better positioned to anticipate what is around the corner. As a result, availability has increased by 5%. " Russell Smallridge "

Introduction

MEON, a leader in line marking and surface repair solutions, has always prided itself on its traditional family values and commitment to quality. With a diverse range of industry applications, from aerospace to highways, MEON continually strives to provide resilient solutions to its customers. As the company gears up for further growth, it recognizes the need to modernize its supply chain to exceed customer expectations and drive efficiency.

Why Slimstock?

MEON’s pursuit of supply chain excellence led them to Slimstock’s supply chain optimization platform, Slim4. Russell Smallridge, the owner of MEON, emphasizes the importance of finding the right tool and partner: “It was crucial to select a solution that could handle the complexities of our supply chain and integrate seamlessly with our existing ERP, Netsuite. Additionally, we needed a partner to elevate our planning team's knowledge.”

Following an extensive market review, MEON chose Slim4. “We had seen the results Slim4 helped other businesses achieve. Given the experience of Slimstock’s team, we were confident they were the right partner to help us meet our ambitious supply chain KPIs,” adds Russell.

Challenges

MEON’s evolution from an import and export agency to a leading supplier in its field presented new challenges. The company needed to modernize its supply chain to keep pace with its growth. Russell explains: “As our business expands, it is vital we continue to develop our operations to meet our customers' needs.”

حلولنا

Efficiency Boost

Previously, MEON's planning team relied on spreadsheets to manage inventory, leading to static processes and time-consuming tasks. With Slim4, MEON worked closely with Slimstock’s consultants to define more efficient inventory management processes. “As part of Slimstock’s robust implementation, our team also completed a comprehensive training program,” Russell notes.

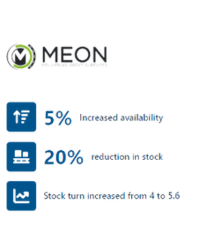

The impact was immediate. “Equipping our team with the right tools and knowledge allowed us to make smarter supply chain decisions. Since implementing Slim4, our stock turn has increased from 4 to 5.6,” shares the Supply Chain Manager. The implementation has reduced the time spent on stock management by up to 50%, allowing more investment in vendor management without additional human resources.

Strategic Assortment Decisions

Slim4 has also enabled MEON to focus on products that matter most. The dynamic stocking policy and ABC functionality within Slim4 help identify poor-performing product lines, allowing for more rational stocking decisions.

“We now focus our time and investment on our top items to ensure flawless reliability. By setting low-value products to non-stock, we’ve reduced overall inventory levels by 20%, freeing up working capital for other business areas,” highlights Russell.

Enhanced Visibility

With Slim4’s powerful forecasting engine, MEON has improved visibility throughout its supply chain. The planning team can now quickly build accurate forecasts and demand plans by considering factors like volatility, product lifecycle, and seasonality.

“We are now much better positioned to anticipate future demand, which has increased our availability by 5%. Aligning inventory levels with forecasted demand ensures customer orders are fulfilled on time and in full without increasing excess stock,” explains the Supply Chain Manager.

Next Steps

Extremely satisfied with the progress, Russell and his team are committed to further efficiency improvements throughout MEON’s operations. Summarizing the success of the optimization project, Russell concludes: “From what I’ve experienced so far, I can certainly recommend Slim4 as a valuable stock management toolkit. As we embark on the next steps of our optimization journey, we are excited to strengthen our partnership with Slimstock.”

"MEON’s successful partnership with Slimstock and the implementation of Slim4 have not only streamlined their supply chain but also positioned the company for future growth and success."