How RFID Warehouse Management Fixes Stock Errors and Supercharges Flow in 2025

Posted on June 10, 2025📑 Table of Contents

Manual inventory tracking has long been the Achilles’ heel of warehouse operations. It leads to stock inaccuracies, processing delays, and shrinkage — all of which hurt profitability and customer satisfaction. If you want to understand the root causes of inventory inaccuracy most managers overlook, this breakdown reveals the most common operational failures. As warehouses scale or deal with increased order volumes, the cracks in traditional systems become impossible to ignore. This is exactly where a modern RFID warehouse management system changes the game. By replacing error-prone manual processes with real-time, automated tracking, RFID transforms how warehouses handle stock, speed, and accuracy — without increasing labor.

This article is written for inventory managers and logistics managers who are frustrated with outdated systems and seeking smarter solutions to improve accuracy, efficiency, and control. While RFID has transformed how warehouses track stock, many organizations are now moving toward unified visibility systems. Learn more about why businesses are upgrading to smarter inventory platforms that combine RFID, AI analytics, and ERP synchronization for a complete real-time view.

You’ll discover how RFID solves long-standing operational problems and transforms inventory accuracy, stock visibility, and overall warehouse flow. Whether you’re exploring RFID for the first time or validating a potential investment, this guide gives you the insights and strategies to make a confident decision.

How RFID Improves Inventory Accuracy in Warehouses

If you’re still relying on barcode scans, spreadsheets, or manual counts to track inventory, you’re losing visibility the moment a pallet hits the dock. For inventory managers and logistics teams, that means shrinkage, slow picks, lost time, and zero trust in the system. Not sure how RFID stacks up against traditional barcodes? This RFID vs barcode comparison covers cost, speed, accuracy, and ROI across real warehouse environments.

RFID changes that. It doesn’t just automate scanning — it replaces it with passive, real-time visibility.

Imagine this: A pallet arrives at your receiving dock. No one needs to scan a barcode. As it rolls through a gate, an overhead RFID reader logs it instantly — tag, quantity, location, timestamp — all captured automatically. Your WMS is updated before anyone even touches a screen.

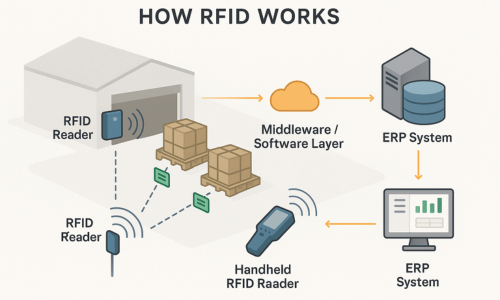

Here’s how the components come together:

- Tags: Attached to cartons, pallets, or individual SKUs

- Readers: Installed at dock doors, on forklifts, or handheld for cycle counts

- Software: Integrates with your WMS/ERP to track inventory movement in real time

And unlike barcodes, RFID doesn’t need line-of-sight. You can scan an entire rack or aisle without stopping to aim or trigger — one reason why more warehouses have modern RFID systems compare to barcodes in real-time tracking

This is not just about speed — it’s about certainty. It’s knowing that the right product, in the right quantity, is in the right place — without relying on human input.

What Makes RFID Better Than Manual Systems?

Traditional inventory systems depend on barcode scans or manual entries. These require human action at every step — scanning SKUs, logging data, double-checking quantities. This leads to errors, delays, and blind spots between stocktakes.

RFID changes the game by enabling passive, continuous tracking:

- Items are detected automatically as they move in and out of zones

- Inventory levels update in real time, not once a day or week

- Human interaction is minimized, reducing both labor and risk

By shifting from batch updates to always-on visibility, RFID creates a warehouse environment where inventory is always accurate, auditable, and instantly accessible.

How RFID Solves Inventory Errors and Shrinkage

What Are the Benefits of Real-Time RFID Updates?

Traditional stock takes are slow, disruptive, and painfully manual. They require workers to pause operations, scan SKUs one by one, and hope nothing gets missed or double-counted.

RFID eliminates that chaos. Planning your rollout? Follow this 30–60 day pilot plan with pass/fail KPIs.

With RFID, every item update is instant and automatic. As inventory moves through your warehouse — whether it’s being received, picked, or restocked — RFID readers capture the data passively in real time. No scans. There is no manual entry. No second guesses.

This means:

-

You don’t need to shut down to count stock

-

Inventory levels are always live

-

You have auditable, timestamped movement data for every item

For compliance audits, this level of visibility is invaluable. Instead of digging through spreadsheets, you can show accurate stock movement — by SKU, time, or location — without lifting a finger. RFID provides real-time accuracy, but true efficiency comes when paired with a multi-site warehouse inventory system that connects every site into one network.

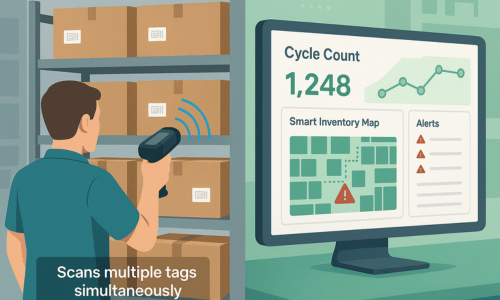

How Does RFID Cycle Counting Work?

If you’ve ever run a cycle count and discovered missing items that “should have been there,” you’re not alone. Shrinkage — whether from theft, misplacement, or mislabeling — is often invisible until it’s too late.

RFID helps you catch it early.

With handheld or fixed RFID readers, you can run rolling cycle counts without halting operations. Walk past a shelf and scan dozens of items in seconds — without touching a single box. Even items on high racks or sealed cartons are picked up. If you’re wondering how cycle counts stack up against full physical audits, here’s a breakdown of the operational pros and cons.

This makes routine verification fast and accurate, which:

-

Reduces ghost inventory

-

Flags discrepancies in real time

-

Builds trust in your numbers — and your team’s performance

More frequent, less disruptive cycle counts lead to better forecasting, less emergency ordering, and higher operational confidence.

How RFID Prevents Inventory Mistakes

The average warehouse loses tens of thousands annually from incorrect inventory data — whether it’s overstocking due to assumed shortages or lost sales due to phantom inventory.

And most of those errors start with manual input.

RFID creates scan-free inventory updates, directly syncing movement data with your warehouse management system or ERP. You remove the need for workers to remember to scan, type, or click — and remove the risk that they’ll get it wrong. Many teams are turning to advanced cycle count techniques that save time and prevent disruption to keep accuracy high without stopping operations.

This results in:

-

Trusted, real-time data for reporting and replenishment

-

Fewer order errors and missed picks

-

Accurate integration with purchasing, shipping, and finance

For logistics managers, it’s tighter control and fewer customer issues.

For inventory managers, it’s real accountability — without more work.

How RFID Improves Warehouse Efficiency

How RFID Streamlines Warehouse Processes

In fast-moving warehouses, every second counts — especially during receiving, picking, and shipping. Traditional workflows depend on manual scans, paper checklists, and constant handoffs, which slow everything down and introduce errors.

With RFID, processing becomes touchless.

-

Receiving: As pallets roll off the truck, fixed readers automatically detect and log the items — no need to scan individual SKUs or open boxes. Your WMS updates in real time.

-

Picking: RFID helps verify picks instantly — no rechecking or barcode rescans. The system confirms the right items are being moved as soon as they leave their slots.

-

Packing & Shipping: Items tagged and verified through RFID can be consolidated and tracked through the final staging area with near-zero error risk.

The result?

👉 Faster dock-to-stock

👉 Streamlined outbound shipments

👉 Higher throughput without increasing headcount

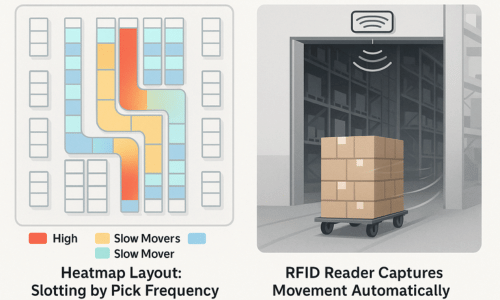

How RFID Improves Slotting and Storage

Inefficient slotting and long travel paths eat up labor and slow down fulfillment. RFID transforms slotting from guesswork to guided optimization.

By tracking inventory movement and item velocity in real time, RFID systems provide data-driven slotting recommendations:

-

High-velocity items near the front

-

Bulky, low-turn items deeper in the warehouse

-

Real-time visibility into bin usage and congestion

And when restocking or put-away is required? Forklift-mounted RFID readers automatically confirm item placement without manual checks — no clipboard, no terminal login, no errors. Paired with mobile tools like PDAs, real-time updates with PDAs improve inventory flow by reducing time spent confirming locations and freeing up staff for higher-impact tasks.

For logistics managers, this means

-

Less backtracking and dead travel time

-

More efficient labor allocation

-

A layout that evolves with your demand patterns

What Operational Insights Can RFID Provide?

Without real-time data, warehouse planning becomes reactive. Supervisors rely on tribal knowledge or outdated reports to assign tasks, forecast space needs, or plan replenishment.

RFID replaces guesswork with live intelligence.

-

Dashboards show what’s arriving, where inventory is located, and what’s low

-

Utilization data reveals which zones are underused or congested

-

Flow insights help optimize staging, routing, and staff planning

When RFID is integrated with your WMS or ERP, you’re no longer planning based on what should be in stock —you’re planning based on what is.

And that means fewer surprises, fewer delays, and far better decisions at every level of the operation.

What ROI Can You Expect from RFID Systems?

For decision-makers evaluating RFID, it’s not just about technology — it’s about outcomes.

Here’s what the best-run warehouses see after adopting RFID systems:

Accuracy that Actually Holds Up

Barcodes rely on perfect human execution. RFID removes that dependency.

Warehouses implementing RFID routinely achieve inventory accuracy above 99.9%. That means:

-

Fewer mispicks

-

Less time spent chasing ghost inventory

-

Increased trust in your WMS data

When inventory is accurate, everything improves: cycle times, customer fulfillment rates, audit scores, and even morale on the floor.

Time Savings Across the Board

-

Receiving becomes scan-free

-

Picking is instantly verified

-

Replenishment is optimized in real time

-

Stock takes and cycle counts are done without disruption

In most operations, RFID saves dozens of labor hours per week — time that can be redirected to higher-impact tasks or help scale without growing your team.

How RFID Saves Costs in Warehouse Management

RFID isn’t just efficient — it’s economical over time.

Warehouses report ROI within 12 to 24 months, largely driven by:

-

Reduced labor costs from fewer manual steps

-

Shrinkage control and loss prevention

-

Better space and resource utilization

-

Fewer rush orders caused by stock inaccuracies

Even for mid-sized facilities, these savings compound fast — especially when integrated with existing WMS/ERP infrastructure.

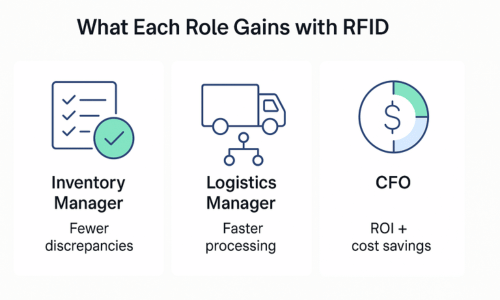

RFID Benefits for Inventory, Logistics, and Finance Teams

Inventory Managers:

-

Fewer discrepancies and reconciliation headaches

-

Cleaner data for audits, demand planning, and reorder points

Logistics Managers:

-

Faster dock-to-stock and improved order turnaround

-

Reduced errors in picking, staging, and shipping

CFOs & Finance Leads:

-

Hard savings in labor and loss

-

Clear cost justification and measurable ROI

-

Improved asset traceability and risk management

Looking to take it further? Here’s how CFOs use StokSmart for measurable inventory profit recovery and operational cost control.