Why Businesses Are Upgrading to Smarter Inventory Platforms: The Real-Time Advantage

Posted on novembre 11, 2025Inventory inaccuracies cost global businesses billions every year — not just in lost stock, but in misinformed decisions, wasted working capital, and unreliable reporting. For most organizations, the culprit isn’t lack of data; it’s the disconnect between systems. ERP platforms, spreadsheets, and warehouse tools all tell slightly different stories about what’s in stock and what’s not — creating a daily fog of uncertainty for finance and operations teams.

As CFOs and Inventory Managers push for tighter control, these inconsistencies expose a deeper issue: legacy systems were built to record data, not to interpret it in real time. Manual cycle counts, delayed reconciliations, and outdated visibility tools turn what should be a strategic advantage into a recurring liability.

That’s why a growing number of businesses are rethinking their approach — shifting from static inventory management to intelligent visibility ecosystems that bring data, accuracy, and decision-making into a single frame. The transformation isn’t about adopting new software; it’s about reclaiming truth in numbers — and that’s exactly where next-generation platforms like real-time inventory intelligence systems are changing the game.

The Inventory Reality Gap No One Admits Openly

Every CFO believes their ERP data is “accurate enough” — until an audit exposes a completely different truth sitting in the warehouse. This is the inventory reality gap: the growing disconnect between what your systems show and what actually exists on the floor.

It starts small — a few units missing, a wrong SKU entry, a delayed update — but those inconsistencies multiply. By the end of a quarter, they distort everything from cost of goods sold (COGS) to replenishment planning. The numbers in financial reports look clean, but they’re built on assumptions, not evidence.

Legacy ERP systems weren’t designed for live synchronization. They record transactions — not movements. Warehouse adjustments, returns, transfers, and markdowns often sit unposted for hours or days. Meanwhile, finance continues to forecast and close books on incomplete data. The result?

-

Manual reconciliation fatigue: Teams waste hours resolving mismatched entries.

-

Inaccurate reporting: KPIs fluctuate because base inventory data isn’t unified.

-

Operational blind spots: Decisions are made without seeing real-time stock reality.

For CFOs, this gap isn’t just operational — it’s financial. When inventory truth lags behind accounting, margins erode silently. Modern enterprises are learning that accuracy isn’t about having more data; it’s about connecting it in real time. When businesses rely on outdated systems or inconsistent data sources, discrepancies pile up fast. Understanding how inaccurate inventory records affect your business is the first step toward fixing them — because every missing SKU or delayed report directly chips away at margins and customer trust.

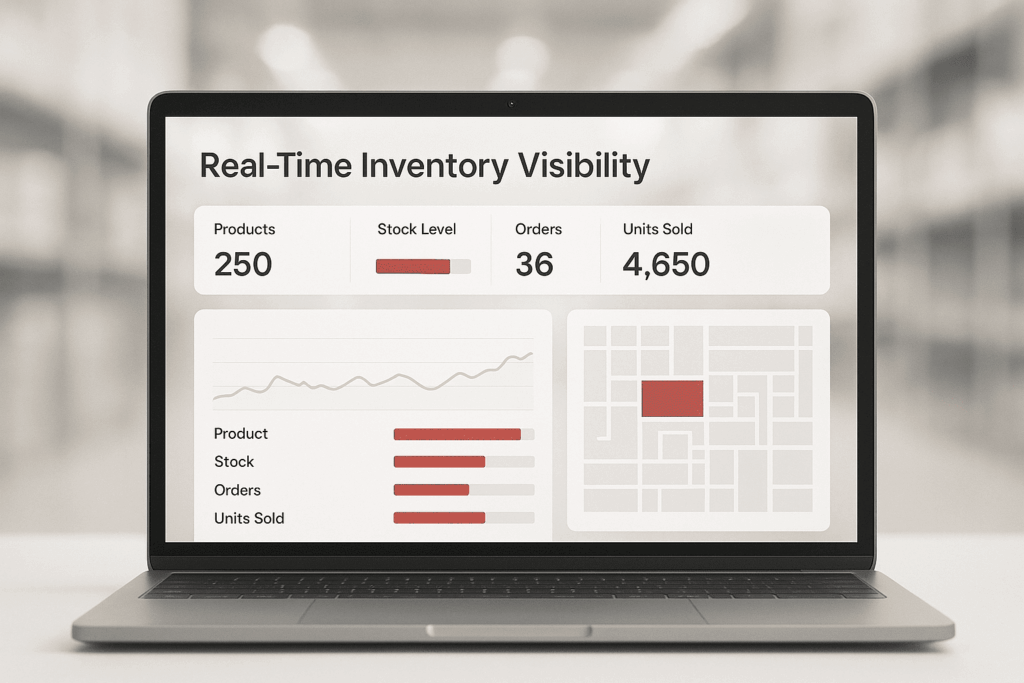

Eliminating Stock Discrepancies with Real-Time Inventory Software

The fastest way to eliminate inventory discrepancies is to stop relying on delayed updates and manual reconciliations altogether. That’s where real-time inventory software changes the game — turning fragmented data into a live, synchronized view of stock across every channel, warehouse, and system.

Instead of chasing mismatched records between ERP and warehouse reports, these platforms create one version of truth. Every sale, return, transfer, or adjustment is captured instantly — so CFOs, Inventory Managers. Warehouse Teams all work from the same accurate baseline.

Here’s how real-time systems eliminate reporting chaos:

-

Real-Time Inventory Tracking: Updates stock movement the moment an item is scanned, picked, or shipped. No batch uploads. No lag.

-

Automated Data Sync: Integrates with ERP, WMS. POS systems to ensure all platforms reflect identical stock levels.

-

Error Prevention: By replacing manual data entry with barcode scanning, RFID. IoT tracking, the room for human mistakes nearly disappears.

-

Continuous Cycle Counting: Instead of year-end disruptions, smart tools perform micro-audits daily to maintain inventory accuracy above 98%.

The result isn’t just operational visibility — it’s financial clarity. When real-time data powers your reports, shrinkage drops, carrying costs stabilize, and working capital finally reflects what’s real, not what’s assumed. Real-time data is no longer a luxury — it’s a baseline expectation. Modern real-time inventory management tools bridge the gap between on-floor operations and executive dashboards, giving teams the confidence to act on accurate, instant updates instead of yesterday’s numbers.

Modern platforms like Oracle Fusion, Zoho Inventory. Zebra Workcloud lead this transformation by bringing the warehouse floor and ERP into perfect sync — ensuring that what’s on paper truly exists in your supply chain.

From Reactive Fixes to Predictive Accuracy — The AI Advantage

Fixing inventory discrepancies is good. Preventing them altogether is where the real value lies. That’s exactly what AI-driven inventory forecasting brings to the table — shifting businesses from reactive adjustments to proactive control.

Modern inventory management software powered by artificial intelligence (AI) et machine learning (ML) doesn’t just record movements; it anticipates them. By analyzing historical sales data, seasonal patterns. supplier performance, it helps decision-makers predict where inaccuracies are most likely to occur — before they impact financials.

CFOs and operations heads gain:

-

Predictive Stock Planning: Algorithms detect demand surges and slowdowns early, minimizing overstocking and stockouts.

-

Anomaly Detection: AI tools instantly flag irregular transactions, helping identify theft, data entry errors, or system mismatches.

-

Smart Replenishment: Automated reorder signals keep inventory levels optimized without excess working capital.

-

Integrated Forecast Dashboards: Unified ERP et WMS data ensure finance and operations teams read from the same real-time source.

Instead of monthly surprises, finance teams get a continuous pulse of truth. This new layer of predictive inventory intelligence means less firefighting, fewer manual adjustments, and better capital allocation — all measurable on the balance sheet. Predictive inventory planning isn’t just about speed — it’s about intelligence. The emerging warehouse technologies for retailers in 2025 already prove that AI-driven insights cut decision delays and forecast errors dramatically, turning static warehouses into dynamic revenue engines.

In short, AI isn’t just modernizing inventory visibility — it’s monetizing it.

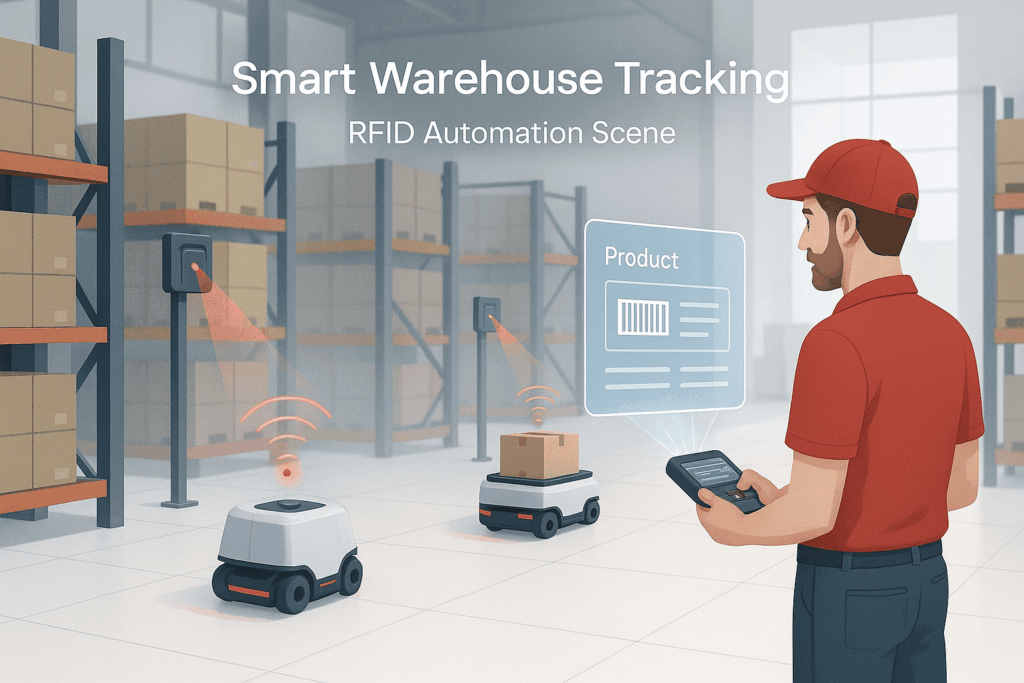

Reducing Shrinkage and Human Error with Smart Warehouse Tracking

Every CFO knows that even a 1% inventory shrinkage rate can quietly drain thousands from the bottom line. What’s worse? Most losses don’t come from theft — they come from human error et data blind spots buried in outdated warehouse workflows.

That’s where smart warehouse tracking software makes a measurable impact. Instead of spreadsheets and guesswork, it delivers a live, traceable map of every product’s journey — from inbound receiving to outbound dispatch.

Here’s how leading systems stop shrinkage before it starts:

-

Real-Time Visibility: Every stock movement — whether scanned, transferred, or adjusted — is instantly logged, giving finance teams full transparency.

-

RFID & Barcode Tracking: Automated capture reduces manual input errors and builds a clear audit trail for every SKU.

-

Access Control & Security Integration: Smart WMS platforms link with digital access systems to monitor who handled what, when, and where.

-

Cycle Counting Automation: Regular micro-counts replace disruptive year-end audits, maintaining >98% inventory accuracy.

-

Analytics for Loss Prevention: AI-driven dashboards analyze deviation patterns, helping detect theft, spoilage, or process loopholes.

Modern platforms like SAP EWM, Oracle WMS Cloud. Manhattan Active WMS combine automation and data intelligence to create a secure, self-correcting environment. They don’t just track inventory — they protect profit margins by eliminating the invisible losses that traditional systems overlook. Shrinkage doesn’t just “happen.” It’s preventable with tech that tracks every movement in real time. Solutions built around RFID warehouse automation close the gap between physical stock and recorded data — making loss prevention measurable, not hypothetical.

In short: what used to be an audit nightmare is now a continuous feedback loop of visibility, accountability, and control.

Synchronizing ERP and Inventory Data — The Missing Link in Most Enterprises

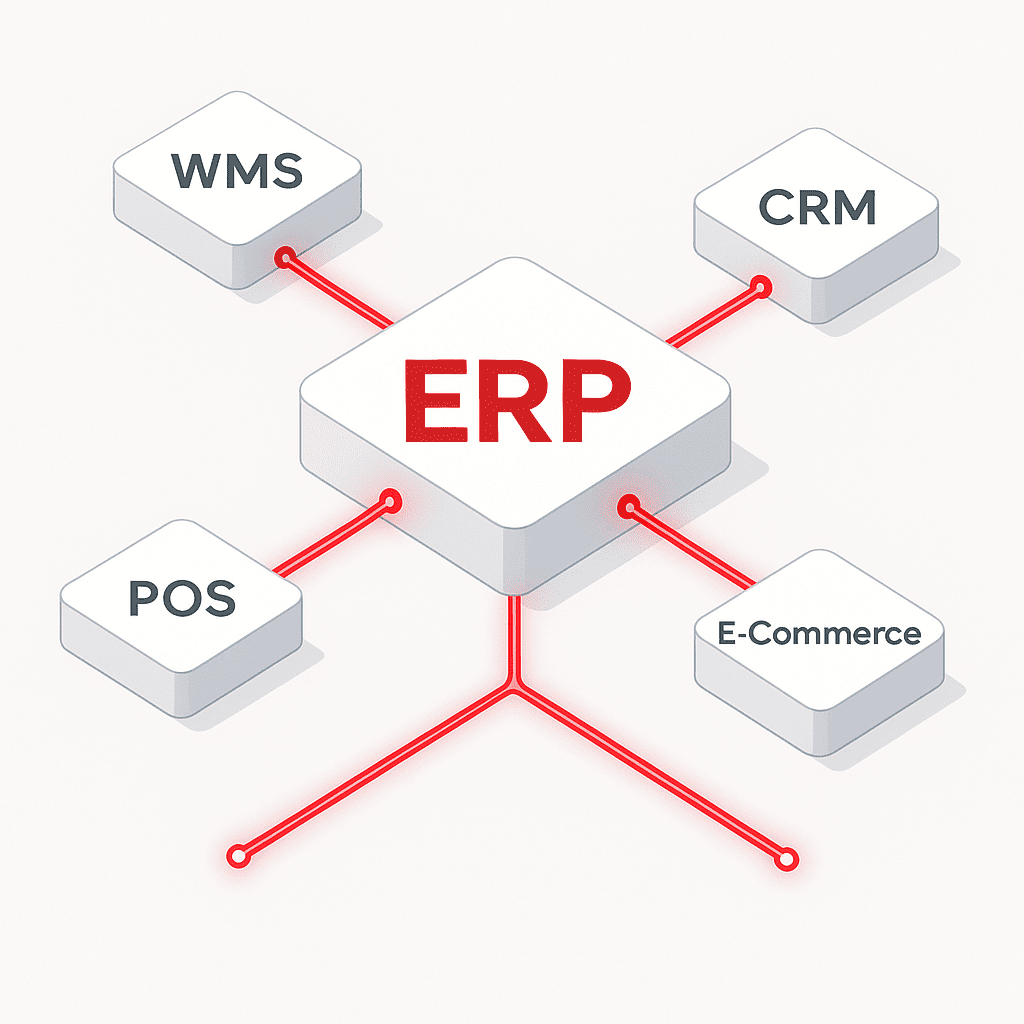

Even the most advanced ERP systems can’t guarantee inventory accuracy if data is disconnected. The reality? Most organizations operate in silos — finance runs on ERP data, while warehouse teams rely on separate WMS or spreadsheets. Between these systems lies a blind spot where inventory discrepancies, delayed updates. duplicate entries thrive.

That’s where an integrated inventory tool makes all the difference. By syncing ERP, warehouse. sales data in real time, it creates a single source of truth across your entire supply chain. Every adjustment, return, or transfer automatically flows into your ERP, eliminating the manual data entry that causes costly mismatches.

Here’s what real-time ERP integration delivers:

-

Instant Data Synchronization: Inventory updates reflect across ERP, WMS, and CRM systems simultaneously.

-

Automated Reconciliation: Every transaction — from purchase orders to cycle counts — is validated and matched automatically.

-

Unified Financial View: COGS, stock valuation, and availability are aligned in one dashboard, giving CFOs live control over financial accuracy.

-

Reduced Manual Labor: Teams no longer waste hours cleaning up data; automation ensures integrity by design.

-

Scalable Integration: Whether through Zapier, Boomi, or native APIs, integration can be customized for multi-system environments.

Tools like Kissflow ERP Sync, Fulfil.io. Xorosoft are leading the way by merging financial precision with operational visibility. When every unit movement updates your books in real time, you’re not just managing stock — you’re managing truth. Disconnected ERPs create data blind spots that cost serious money. The fix? Multi-site warehouse inventory control software that syncs every transaction across systems, keeping numbers accurate from shelf to balance sheet.

The outcome?

Fewer reconciliation headaches. Faster closes. Stronger trust between finance and operations.

The Shift to Smarter Platforms — Why Modern Businesses Are Upgrading

A quiet revolution is happening in how enterprises manage their stock. Businesses aren’t just looking for “inventory software” anymore — they’re searching for intelligence systems that think, learn, and act faster than humans ever could.

Traditional tools were built to record what happened. Modern platforms are designed to anticipate what will happen next. That’s why global retailers, distributors, and manufacturers are upgrading to smart inventory platforms — not to replace people, but to remove the blind spots that people can’t see in time.

The biggest drivers behind this shift:

-

Real-Time Data Unification: Every transaction, from barcode scan to ERP posting, syncs automatically — no silos, no waiting.

-

AI & Predictive Logic: These systems analyze movement trends to prevent stockouts, overstocking, and mismatched valuations before they happen.

-

End-to-End Visibility: Finance, warehouse, and procurement teams all see the same dashboard, powered by live analytics et real-time alerts.

-

Scalability and Security: Cloud-native architectures make it possible to expand globally without losing data integrity or compliance.

What’s truly changed is intent: businesses are no longer buying inventory tools; they’re investing in decision intelligence. This shift becomes unavoidable when scaling inventory operations, as legacy platforms struggle to keep pace with growing volumes, locations, and execution complexity.

When an organization connects its data, automates its audits, and eliminates guesswork from its financials — that’s not just an upgrade. That’s a transformation.

And for teams seeking that transformation, StokSmart represents the next generation of real-time accuracy — a unified system built not just to manage inventory, but to manage confidence.

The New Standard for Inventory Excellence

The best companies in the world no longer chase inventory accuracy — they own it.

They’ve moved past the old rhythm of spreadsheets, delayed ERP syncs, and end-of-month surprises. What they operate on now is a live truth — a continuously updated, connected, and intelligent view of their entire supply chain. Companies ready to stop guessing and start optimizing are already adopting StokSmart inventory profit recovery software. It’s the natural next step for CFOs and inventory leaders who want clarity, not complexity.

That’s the new benchmark.

And the difference between companies that merely survive audits and those that scale profitably comes down to one thing — clarity.

- Clarity in what’s on hand.

- Clarity in what’s moving.

- Clarity in what it costs — right now, not yesterday.

Platforms like StokSmart aren’t just digital tools — they’re financial instruments that turn operational visibility into measurable ROI. When every count, cost, and correction happens in real time, CFOs don’t just manage stock — they manage certainty.

Because in today’s markets, accuracy isn’t a metric. It’s a mindset.

So, if your systems still require reconciliation to find the truth — maybe it’s time to experience one that is the truth.