How to Improve Stock Accuracy in Supermarkets | Proven Solutions for Success

Posted on أكتوبر 14, 2024Stock accuracy is at the heart of efficient supermarket operations. Poor inventory management leads to shrinkage, wasted resources, and dissatisfied customers. Improve stock accuracy solutions in supermarkets often face significant challenges in maintaining accurate inventory, from managing vast quantities of stock to adopting effective counting methods. This blog delves into these issues and offers innovative solutions—from traditional practices to technology-driven strategies—to boost profitability and streamline operations.

Challenges in Stock Accuracy for Supermarkets

-

Managing Vast Quantities of Inventory:

Supermarkets handle thousands of SKUs and millions of items in stock. For example, a supermarket chain like Walmart stocks over 500,000 items at any given time. Such scale makes tracking and auditing complex, leading to discrepancies. Additionally, seasonal spikes and promotional activities further complicate inventory accuracy, often causing mismatches in stock levels.

-

Labor-Intensive Counting Methods:

Traditional stock counts require significant manpower. A typical supermarket might need 50–100 employees and numerous barcode scanners to complete a single overnight count. This process increases operational costs and disrupts workflows. For smaller supermarkets, the lack of resources often leads to skipped audits, which further impacts stock accuracy.

-

Infrequent Stock-Takes:

Annual stock-takes result in inventory accuracy rates as low as 65%, as discrepancies accumulate throughout the year. For example, errors in sales data, returns, and unrecorded shrinkage contribute to significant financial losses. Over time, these inaccuracies result in overstocking, stockouts, and revenue loss.

-

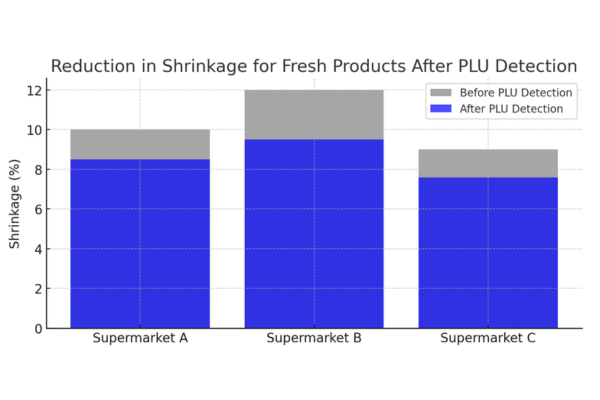

Complexity in Barcode Management:

Supermarkets use various barcodes (e.g., PLUs for fresh produce, UPCs for packaged goods). Ensuring scanners correctly detect all formats can be challenging, causing up to 3% in annual sales losses due to inventory mismanagement. Additionally, manual errors in entering PLU codes for fresh items can lead to significant discrepancies.

Proven Solutions to Improve Stock Accuracy

Altavant Consulting provides technology-driven solutions to help supermarkets improve their accuracy with stock accracy solutions efficiently and cost-effectively.

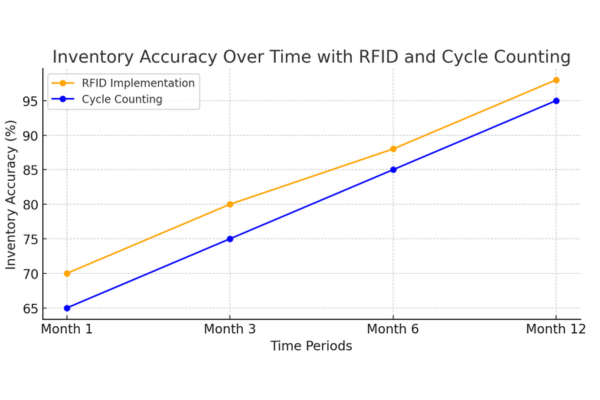

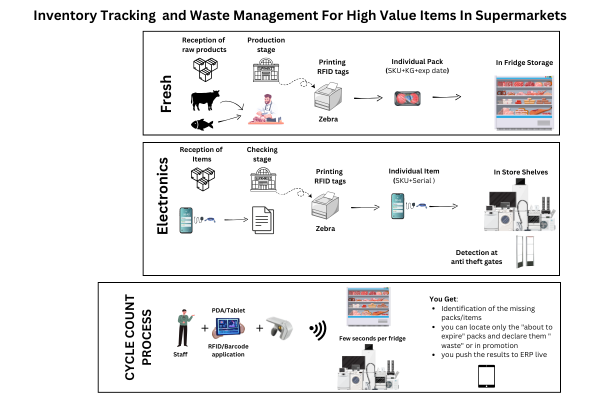

Adopt Advanced Inventory Technology

Leverage tools like RFID (Radio Frequency Identification) for real-time stock tracking. RFID in retail not only streamlines stock audits but also reduces manual errors. By automating the tracking process, supermarkets can ensure accurate inventory without relying heavily on manual efforts.

- Case Study: A mid-sized supermarket chain reduced shrinkage by 22% within one quarter by using RFID to promote near-expiry products. Furthermore, RFID-enabled systems allowed the chain to monitor inventory trends more effectively, reducing stockouts during peak sales periods.

Implement Regular Cycle Counts

Cycle counting involves frequent audits of high-priority SKUs rather than annual stock-takes. This ensures consistent accuracy without disrupting operations. Frequent counts help identify discrepancies early, allowing supermarkets to address issues proactively.

- Example: Weekly cycle counts for high-value items like liquor and electronics helped one supermarket improve inventory accuracy by 30% in six months. This method also allowed the store to align inventory levels with customer demand, minimizing waste.

Utilize ABC Analysis for Prioritization

Classify inventory based on revenue or risk:

- A-Ranked Items: High-value, high-demand products. Count frequently.

- B and C Items: Moderate to low value, counted less often.

This method ensures resources focus on critical products. For example, supermarkets focusing on A-ranked items such as premium meats and electronics reported a 15% improvement in stock optimization within one quarter.

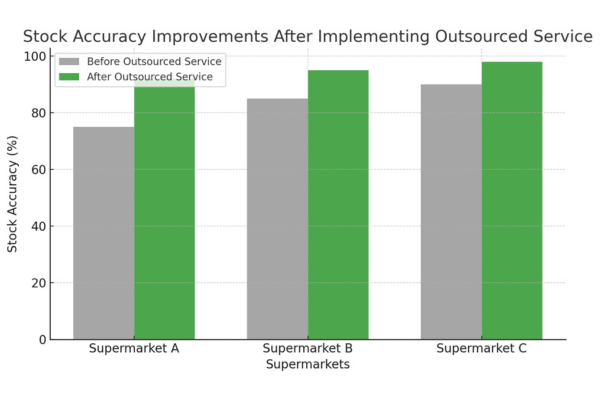

Outsource Stock Management Services

Outsourcing to experts ensures accurate, efficient stock counts. Providers like Altavant Consulting bring pre-configured tools and trained teams, reducing in-house workload. Outsourcing also eliminates the need for costly overnight stock audits by in-house staff.

For supermarkets seeking a hands-off solution, Altavant Consulting offers a Full Outsource Service that delivers timely and accurate stock counts with minimal effort from the supermarket team.

- We bring the team and tools: Our expert team arrives with pre-configured barcode scanners, loaded with your item masters and barcodes, eliminating the need for your in-house resources.

- On-the-spot results: By the end of the stock count, we provide the results immediately. For example, one of our clients, a large grocery chain, reported stock accuracy improvements from 75% to 92% after using our technology just twice a year.

- PLU Barcode Detection for Fresh Products: For fresh items like fruits, vegetables, and meats, our scanners come with built-in PLU barcode auto-detection. A mid-sized supermarket using this feature saw a 15% reduction in shrinkage related to fresh products in the first quarter.

How Regular Cycle Counts Improve Stock Accuracy in Supermarkets

For supermarkets that prefer in-house stock audits, Altavant offers a جرد دوري solution that can be integrated into your existing system. This method allows supermarkets to count high-value categories more frequently, significantly reducing errors.

- Flexible Counting Schedule: Our dashboard calendar lets you schedule counts for high-value items more often. Track from the head office who counted the items, who audited, what is the all-year-long count status of each SKU… A supermarket chain we worked with implemented weekly cycle counts for electronics and reduced stock discrepancies by 30% in the first six months.

- SLA-Driven Audits: By implementing Service Level Agreements (SLAs) to ensure regular audits, supermarkets can maintain a high level of accuracy. A recent project with a supermarket that counted its high-value liquor items monthly saw inventory accuracy rise to 98%.

- Real-Time Reporting: Supermarkets using our system get real-time Business Intelligence (BI) reports based on item descriptions, zones, and periods. One retailer improved decision-making speed and reduced stock misplacement by 20% with instant BI feedback.

- AABBCC Ranking Management: By using AABBCC ranking, supermarkets can prioritize counts for high-demand and high-value items. For example, a client that focused on A-ranked products (those generating the most revenue or the most “at-risk products”) improved stock visibility and reduced overstocking by 18% within one quarter. It allows you to run Focus counts instead of category counts, “count what matters”.

- RFID in supermarkets: RFID in supermarkets is not only for luxury items: the affordability of the consumables, the ease of the encoding process (at the production step for the fresh products or supplier level for electronics) make the business model relevant to supermarkets. Save time to identify the “about to expire” items, change the price only for these products with a click of a button, run daily counts in the electronic/games sections…

Enhancing Stock Accuracy Through Technology

Real-Time Reporting with Business Intelligence (BI)

BI tools provide instant feedback on inventory management trends, discrepancies, and zone-specific data, enabling quicker decision-making. Supermarkets that adopted BI platforms reported a 20% reduction in misplaced stock and improved replenishment strategies.

RFID’s Expanding Role

RFID technology, once reserved for luxury items, is now accessible for supermarkets. It helps:

- Track perishables.

- Automate price updates for near-expiry items.

- Conduct daily counts in electronics sections.

- Example: A supermarket using RFID for perishables saw a 25% increase in sales of near-expiry items through automated discount triggers.

Integration with AI and Machine Learning

AI-driven tools analyze patterns, forecast demand, and identify potential shrinkage points. For example, AI can predict peak sales periods and adjust inventory levels accordingly. Machine learning algorithms also help optimize stock placement for faster order fulfillment.

Real-Life Impact of Improved Stock Accuracy

1. Financial Benefits

One supermarket saved over $200,000 annually by using RFID for high-value products. The technology enabled inventory checks in minutes rather than hours, freeing up resources for other operational needs.

2. Operational Efficiency

Weekly cycle counts reduced stock discrepancies by 20% and improved replenishment accuracy, leading to fewer stockouts. These improvements also enhanced staff productivity by streamlining the counting process.

3. Customer Satisfaction

Accurate inventory ensures product availability, enhancing the shopping experience. Research shows that 84% of customers won’t return after a disappointing purchase experience. By ensuring stock accuracy, supermarkets can retain loyal customers and attract new ones.

Conclusion

Stock accuracy is essential for minimizing losses, streamlining operations, and boosting profitability in supermarkets. By adopting advanced technologies, implementing cycle counts, and prioritizing high-value SKUs, supermarkets can achieve real-time inventory control and elevate their operations. Additionally, leveraging AI and BI tools ensures smarter, data-driven decisions that drive long-term success.

By choosing Altavant Consulting’s stock management solutions, supermarkets can improve stock accuracy, reduce resource dependence, and gain real-time insights that will transform their operations.